EZCNC Fiber Laser-GL Series

EZCNC fiber laser cutting machine, IPG laser from Germany , with good cutting quality, cutting speed, low maintenance cost.

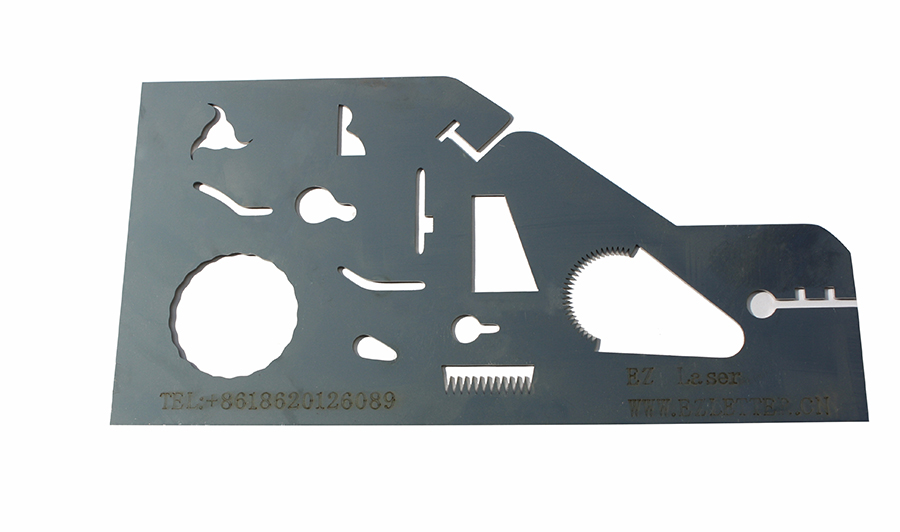

| EZCNC Fiber Laser Cutting Machine is a perfect combination of high-tech fiber laser technology and innovative dual ballscrew with driven nut. EZCNC fiber laser cutting machine has perfect cutting quality, extremely fast cutting speed, extremely low cutting and maintenance cost, it is the perfect choice for your metal cutting! The laser cutting machine has both cutting and hollowing processes; tube and sheet cutting have both, the tube-sheet integrated laser cutting machine uses "invisible light" to outline square tubes, round tubes, and plane, it demonstrates its multi-functional and practical features and the advantages of its full-featured gantry dual-drive structure. Strong and efficient imported gear and rack transmission structure, to upgrade its cutting performance and stability again, with a self-centering fixture system to let you appreciate its high precision, high quality and high stability. |

|

Brief description of mechanical structure |

|

Brief description of electrical part |

|

Control System Using the excellent CypCut laser cutting control system, which integrates file reading, design, output and processing control, the software can complete the whole process from design to processing. The software provides a wealth of laser cutting process parameters, flexible layout and tool path editing capabilities, introducing extraction, bridging, coedge, spot compensation, curve smoothing, splitting, merging, and automatically distinguishing internal and external mold functions. It provides speed PWM real-time power adjustment, gradual perforation of explosion-proof holes and other special processes. |

|

Automatic tracking system |

|

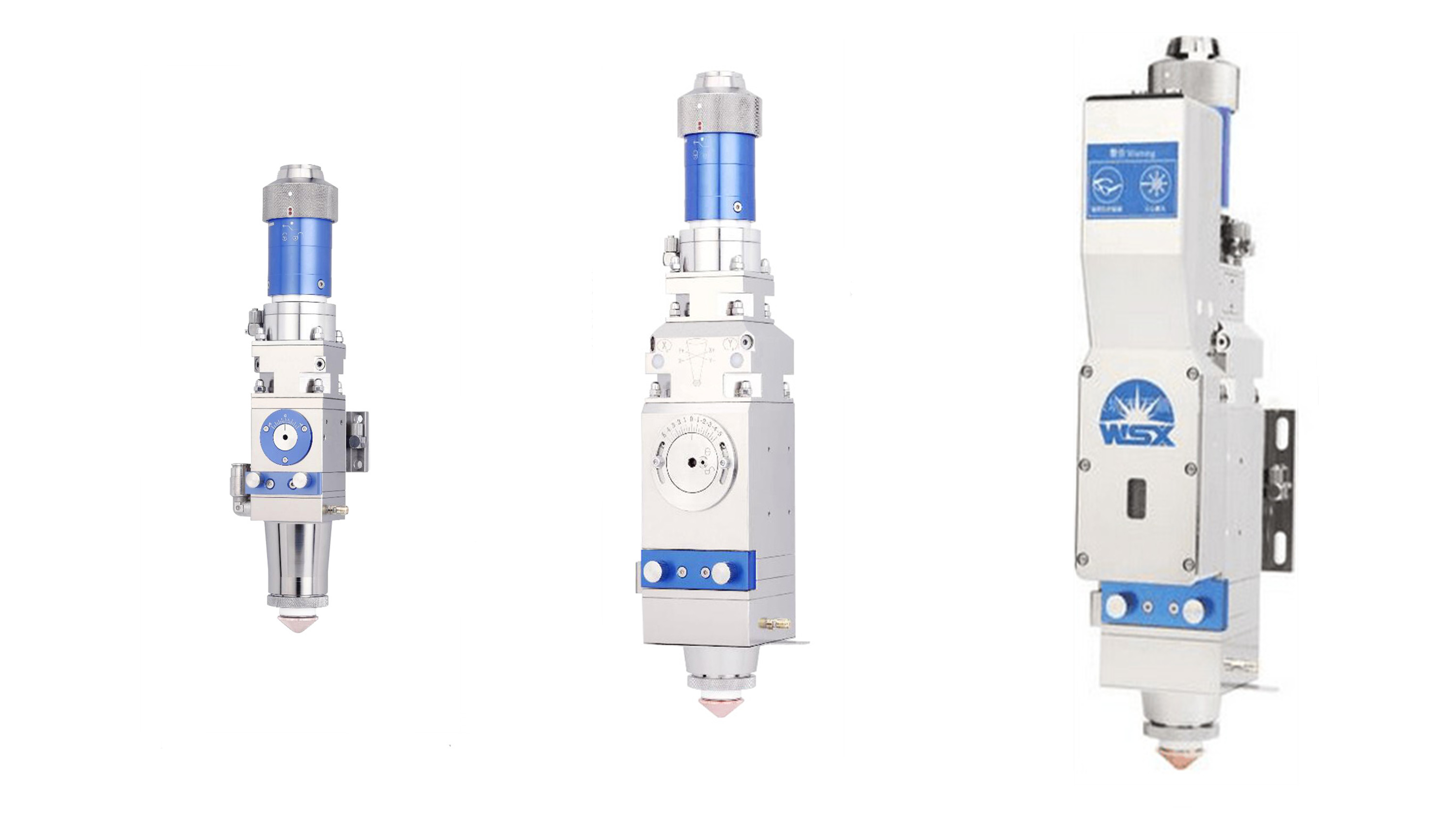

Laser and Cutting Head 1. Imported GW fiber laser, power is 4000W, has the characteristics of low cutting cost, good cutting quality, fast cutting speed and low maintenance cost. |

|

Model |

GL510 |

||

|

Size(Work area) |

1.5m x 3.0m |

||

|

Laser source |

IPG laser generator/ GW laser generator |

||

|

Laser Power |

1KW/1.5KW/2KW/3KW |

||

|

Laser Wave Length |

1070nm |

||

|

Max Cut Thickness |

1000W:Stainless Steel:6mm、Carbon Steel:8mm |

||

|

Ref Cut Speed |

1000W:1mm stainless steel 20m/min |

||

|

X-dual Ballsrew |

√ |

||

|

Servo |

Yaskawa |

||

|

Max Speed |

30m/min |

||

|

Z Clearnce |

150mm |

||

|

Controller |

CypCut |

||

|

Vacuum Zone |

2 |

||

|

Power |

380V/20A |

||

|

Weight |

2.5Ton |

||

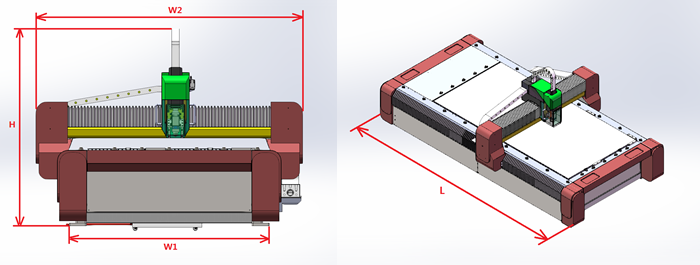

| Model | L(mm) | W1(mm) | W2(mm) | H(mm) |

| GL1313 | 2592 | 1650 | 2232 | 1378 |

| GL1325 | 3862 | 1650 | 2232 | 1432 |

| GL1530 | 4370 | 1870 | 2486 | 1432 |

| GL1550 | 6358 | 1904 | 2564 | 1378 |

| GL2030 | 4370 | 2282 | 2974 | 1378 |

| GL2040 | 5394 | 2282 | 2974 | 1378 |

|

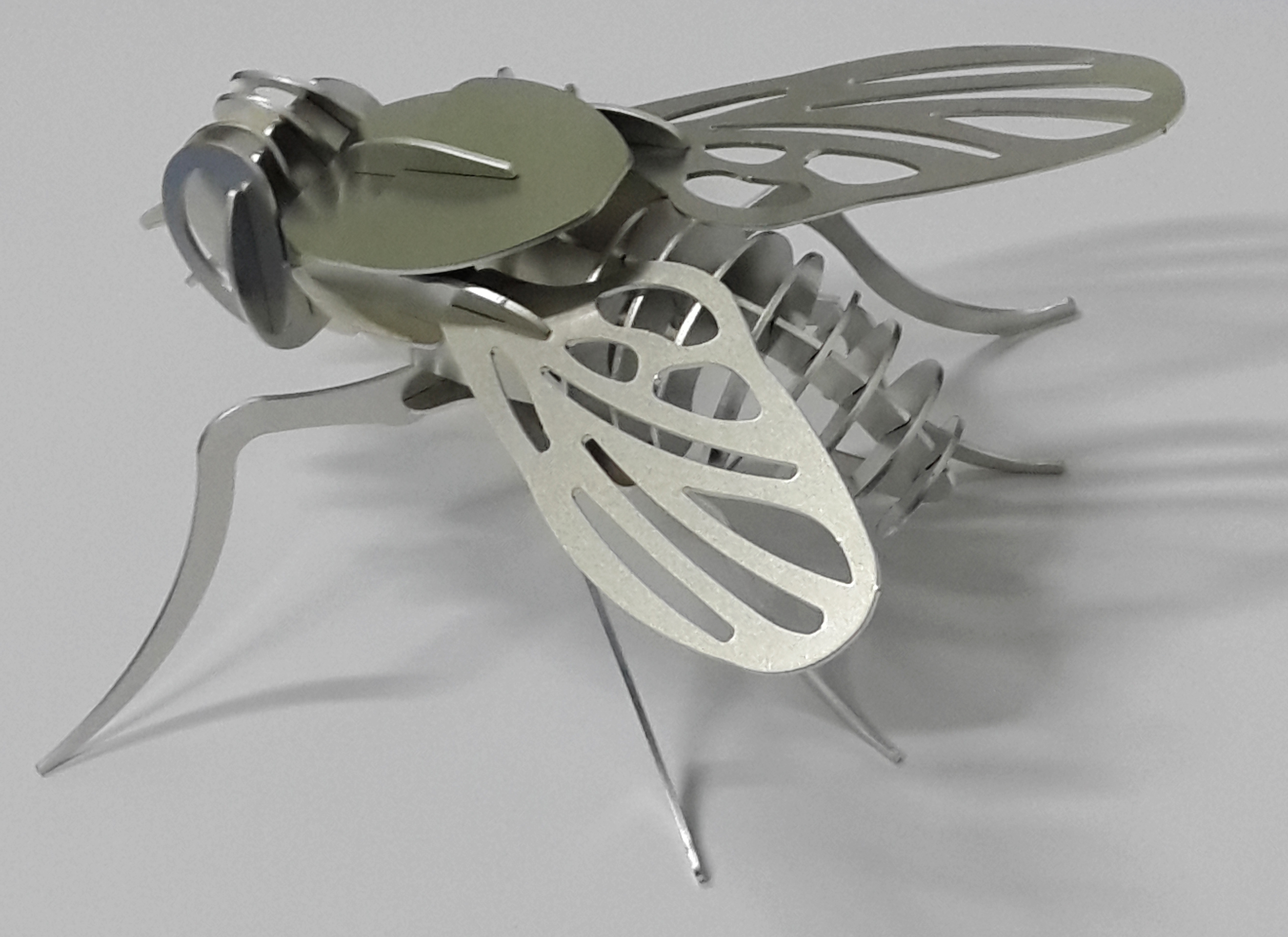

Applied materials: carbon steel, stainless steel, copper, aluminum, galvanized sheet, copper, brass, aluminum alloy, titanium alloy, manganese alloy, electrolytic plate and other metal materials. |

|

Widely used in: sheet metal processing, aerospace, aviation, electronics, electrical, high-speed rail and subway accessories, auto parts processing, food machinery, textile machinery, engineering machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, kitchen supplies , tool processing, decoration, advertising and other metal materials processing and manufacturing industries. |